News

Energy Efficiency Innovation on the Ground: Highlights from the EELA Study Tour in Sweden

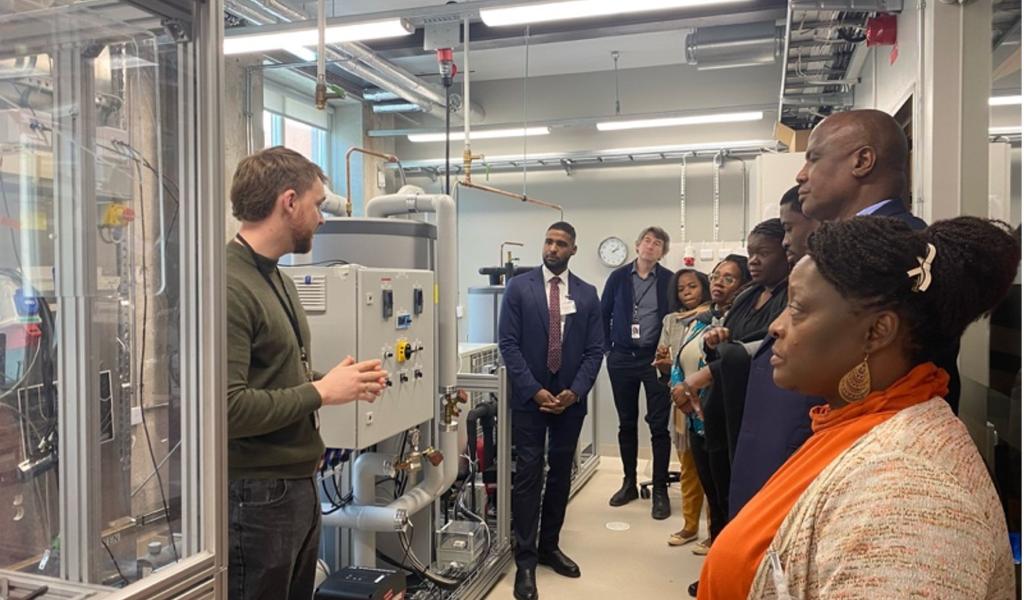

As part of the EELA Expert and Partner Meeting in Stockholm, the program’s stakeholders took part in a series of study tour activities aimed at exploring concrete, technology-based approaches to energy efficiency. These visits complemented the technical discussions of the event by offering firsthand exposure to innovative components and systems that can help shape more sustainable energy futures.

The tour included a visit to the Swedish Energy Agency’s test laboratory, a facility established to support the assessment of energy-efficient lighting solutions. In operation since 2011, the lab carries out a wide range of tests to evaluate the performance and overall quality of lighting products, ensuring they meet high standards throughout their entire life cycle, from production and use to recycling. Unlike many energy agencies that typically outsource such testing to third parties, the Swedish Energy Agency manages these operations in-house. This approach provides the Agency with valuable internal expertise, reinforcing its ability to support energy performance standards in a systematic manner.

The EELA delegation also visited Xylem, a company offering advanced pumping solutions tailored to various industrial and environmental needs, including agriculture, mining, construction, and wastewater management. A key point of interest was the company’s pumping systems capable of handling large debris and solid materials within water or wastewater flows. This feature is particularly relevant for contexts with high levels of debris or stormwater, as it reduces maintenance demands while remaining energy and cost-efficient. The visit highlighted how well adapted technical solutions can improve resilience and sustainability in water management systems.

The third stop on the study tour was Munters, a company specializing in evaporative cooling, dehumidification, and heat recovery technologies. Participants were introduced to advanced equipment and systems designed to optimize climate control in industrial settings while significantly reducing energy consumption. According to company data, Munters’ technologies can cut energy costs by up to 30%, while also enhancing water absorption efficiency. These innovations underscore how targeted upgrades in industrial processes can yield both environmental benefits and operational efficiencies.